3D printing is a type of additive manufacturing, a process that creates three-dimensional objects by building them layer by layer from a digital 3D printing model.

Widely used for rapid prototyping, 3D printing allows designers and engineers to quickly and cost-effectively create and test models. Industries such as aerospace, automotive, and consumer goods use it for custom parts.

3D printing is revolutionising industries by manufacturing prototypes, custom parts, medical implants, prosthetics, and bio-printed tissues tailored to patients' needs. In architecture, it's used to create models and construct full-scale buildings and bridges, enhancing design and construction efficiency. It's also an essential educational tool, helping students understand complex concepts in subjects like engineering, biology, and art.

Here are five astonishing examples of real-world 3D-printed creations that showcase this technology's incredible potential.

3D-printed Violins and Cellos

Photo credit: 3Dvarius

Imagine a violin with a body made of clear resin, its intricate internal structures visible like a work of art. This is the 3Dvarius, a revolutionary electric violin created by Laurent Bernadac. 3D printing allowed Bernadac to achieve a unique design with superior acoustics, proving that 3D-printed instruments can rival, and even surpass their traditional counterparts.

But the innovation doesn't stop there. 3D printing also opens the door to customisation, allowing musicians to personalise the body of their instruments with unique shapes, colours, and materials. The future of music is sounding pretty exciting, thanks to 3D printing designs!

3D-printed Steel Bridge in Amsterdam

Photo credit: Dezeen

In a world-first, Amsterdam unveiled the MX3D Bridge, a fully functional steel bridge built entirely by robots using 3D printing. This groundbreaking project showcases the potential of 3D printing to revolutionise infrastructure development. The bridge was "printed" in layers using robotic arms, resulting in a unique and sustainable design that used recycled steel.

With faster construction time and customizable designs, 3D printing could change how we build bridges and other structures in the future. Not only is building structures this way potentially more efficient, it also helps with sustainability by minimising waste of raw materials and reducing the carbon footprint of construction projects.

3D Printing in Museums

3D printing isn't just about creating the new; it's also helping us preserve the old. Museums are leveraging 3D scanning and printing to breathe new life into damaged or incomplete artefacts. By carefully scanning existing pieces and creating models, they can create precise digital replicas that serve as blueprints for restoration. Missing fragments, weathered details, or even entire sections can be painstakingly recreated and seamlessly integrated into the original artefact, ensuring its preservation for generations to come.

These replicas can also be used to create interactive exhibits, where visitors can touch and feel the artefact that would otherwise be too fragile to handle. Moreover, 3D printing is opening up new avenues for access and education. Museums can create multiple replicas of artefacts, allowing them to be shared with other institutions or used in travelling exhibitions without putting the originals at risk. This democratises access to cultural heritage, making it possible for people around the world to experience and learn from historical treasures.

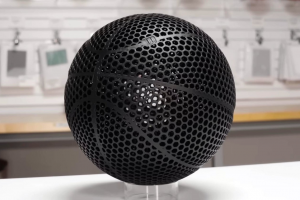

3D-Printed Airless Basketball

Photo credit: Yanko Design

Basketball fans, get ready to be amazed! Wilson has unveiled a prototype basketball that's completely airless. This innovative ball, with its unique lattice structure, is 3D printed in one piece and never needs to be inflated.

The Airless Prototype was conceived as a way to explore new possibilities in sports equipment design and manufacturing. Wilson partnered with EOS, a leading 3D printing company to create a 3D-printed basketball that closely mimics a traditional basketball in terms of weight, size and bounce. While the airless prototype is still in its experiential phase, the future of a durable, eco-friendly, airless ball that never loses its bounce is an exciting one for basketball fans worldwide!

3D-Printed Artificial Coral Reefs

Photo credit: Reef Design Lab

In an effort to combat coral reef destruction, scientists are turning to 3D printing. These artificial reefs, crafted to mimic the complex structures of natural coral, provide a haven for marine life. By creating sustainable habitats, 3D-printed reefs offer hope for restoring biodiversity and protecting our oceans.

In the Maldives, a company called Reef Design Lab has successfully created the world's largest artificial 3D-printed reef. Spanning 220 square metres, the reef was created using design moulds that were generated from thousands of photos to create a 3D model, before being printed and cast, filled with marine concrete and dropped into the ocean. This innovative project showcases how 3D printing can contribute to marine conservation and promote the recovery of damaged ecosystems.

A Future Printed in 3D

These examples are just a glimpse of what 3D printing can achieve. From violins to bridges to life-saving medical devices, this technology is pushing the boundaries of what's possible.

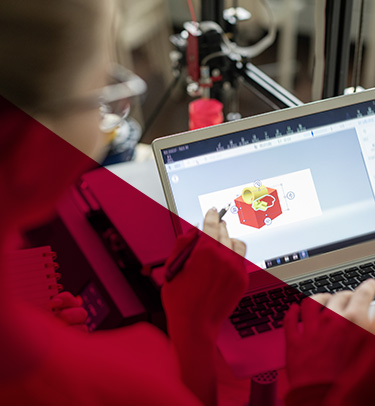

These examples are just a glimpse of what 3D printing can achieve. From violins to bridges to life-saving medical devices, this technology is pushing the boundaries of what's possible. At PSB Academy, our engineering certificate and diploma courses include 3D printing modules. You'll learn to create 3D models with SolidWorks and get hands-on experience with PrusaSlicer 3D printers in our mechanical lab. Additionally, you'll explore various 3D printing processes such as Fused Filament Fabrication (FFF), Stereolithography/Digital Light Processing (SLA/DLP), Selective Laser Sintering (SLS), and Material Jetting. You'll also learn crucial FFF parameters (layer thickness, shell thickness, infill density, supports), how to convert 3D CAD files into STL and G Code using slicer software, and how to operate 3D printers.

Explore PSB Academy's engineering courses today and discover how you can shape the future with 3D printing!

TOP

TOP